In the world of chip technology, demand for smaller and better chips is on the rise. Chips are integrated into more and more products and expectations of what they can do are also growing. The Chip Integration Technology Center (CITC) is designing methods to integrate these chips more efficient and better in three domains.

Consumer goods like smartphones contain more and more chips, but simultaneously, have to be thinner and still highly functional. That is a big demand from the chips in the phones. Barry Peet of CITC explains how the demand for combined chips continues to grow at the same time. “For example, the future demand for photonic chips, which combine the use of both light and electricity, is expected to grow enormously.”

Packaging plays a big role

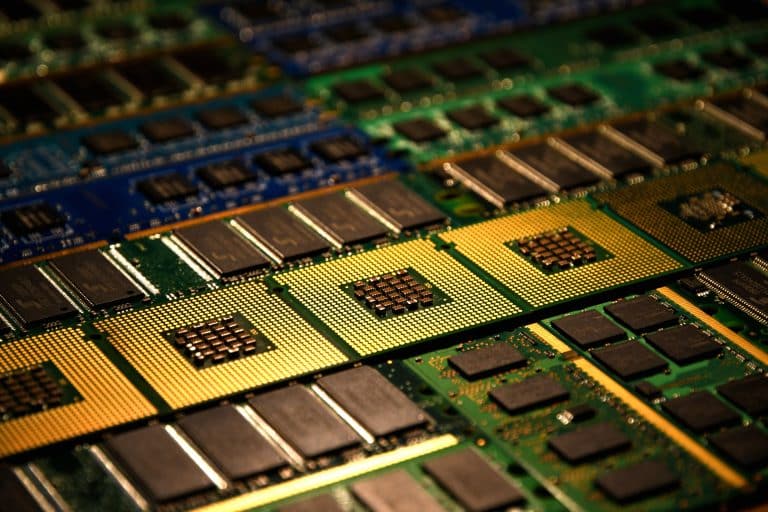

When laypeople talk about chips, they may have something different in mind than the chips that CITC focusses on. “When people talk about a chip, they usually refer to the little black thing that you can find in your phone. For us, that is the packaging. The chip is what’s inside the black packaging.” For a while now, multiple chips have been incorporated into a final product. Integrating these chips into one packaging, is the process that CITC is working on.

“To us, there are three important domains when it comes to packaging. There are high-frequency chips, high-power chips and photonic chips. In the field of high-frequency chips, we are partnering up with NXP. We co-design antennas that are inside a chip, to further increase the performance.”

Barry explains that high-power chips pose very different challenges. “These packages get very hot, and we have to find a way to dissipate that heath. And it must be a solution that has to function for thousands or even tens of thousands of cycles. Therefore, our research also focusses on how packages behave when they are alternately exposed to very high and low temperatures.”

Part of a bigger process

As a company, CITC operates in the back-end of the chip process. Whereas companies in the front-end are involved in the actual production of chips (wafers), CITC provides the techniques to integrate and stack the chips.

“In recent years, we have seen a growing emphasis on the back-end process. New techniques are necessary to be able to develop new generations of packages. We always work based on a need from the industry. That is why we have set up the three domains in which we operate, in collaboration with our clients.”

Recent developments in the process

“We have started to involve different suppliers in our development. This allows them to test their materials and co-develop new materials that are best suited for the final product. At a later stage, we also like to involve equipment suppliers in the process, so that they can help our customers with large volume production of the packages based on the processes we develop”.

Collaborations on campus

CITC has been part of Novio Tech Campus since the very beginning. According to Barry, joining NTC was a no-brainer. “Our three biggest customers, Ampleon, NXP and Nexperia, are located right here on campus. To us, the ecosystem present is crucial. The campus has a strong focus on high tech and packaging, which is exactly our playing field.”

CITC has partnered up with other companies on campus. “For example, we work with packaging company Sencio. They help us by producing limited numbers of prototypes, making our customers very happy. We don’t have the facilities to do these steps ourselves, so this is a great addition to our proposition.”

“One thing we know for certain: we will not leave the campus. We don’t want to, and we can’t lose the close connection to our customers.” CITC also works closely together with TNO and TU Delft. “Our organisation was founded by these strategic partners, and we have been using their infrastructure and available knowledge ever since.”

Looking towards the future

CITC would not have been here without the investment of public funds from the municipality of Nijmegen and the Gelderland province. The organisation intends to put that money to good use in the coming years. “For next year, we are focussing on the further development of our technologies.”

Alongside the development of their technologies, CITC wants to look beyond the Netherlands. Europe wants to become less dependent on chip manufacturers from Asia and America. “Look at the current chip shortage, with entire automotive factories at a standstill. Of course, that is something you want to avoid when moving forwards. We are now emphasising that it isn’t just the chips. It is also about the packaging of these chips. The whole chain should be present in Europe.”

Finally, Barry adds that both CITC and Novio Tech Campus want to focus more on education and training. “For all this to succeed, new people with knowledge about these topics are crucial. That is why we have developed the CITC Semiconductor Packaging Minor, in collaboration with HAN. The lack of highly skilled people is already an issue and that will only get worse over time. That is why we are doing something about it now.”